Complex vs. complicated - How do we create the best possible terminal?

The container handling industry is constantly changing. In addition to developing new or improved products, our main focus for the future is on new kinds of services, such as guaranteed availability and performance.

The ultimate goal of a container terminal is to serve the shipping lines and inland logistics companies as smoothly as possible. At the end of the day, their business performance is measured by the number of container moves. In order to achieve a successful business model, all the stakeholders involved need to construct a competitive container terminal together. Is there room for improvement in our project execution that would prepare the container terminal for faster operations?

Building container terminals is still project oriented

Building a new or refurbished container terminal is a massive project that involves various suppliers, which means the business and operations of a container handling equipment supplier is highly project oriented. For example, Kalmar has a long history in delivering manual container handling equipment to various terminals all around the globe. Even if the work is complicated, we know how to do it after a significant number of repetitions.

To execute such a project, it is possible to agree on a fixed content, fixed price and final delivery date, and then just do it. However, when you build a modern terminal with state-of-the-art automation systems and digital services, the ultimate goal becomes more abstract and a little less clear. It becomes a question of how to plan the final outcome accurately two years before the completion.

A new approach for complex projects

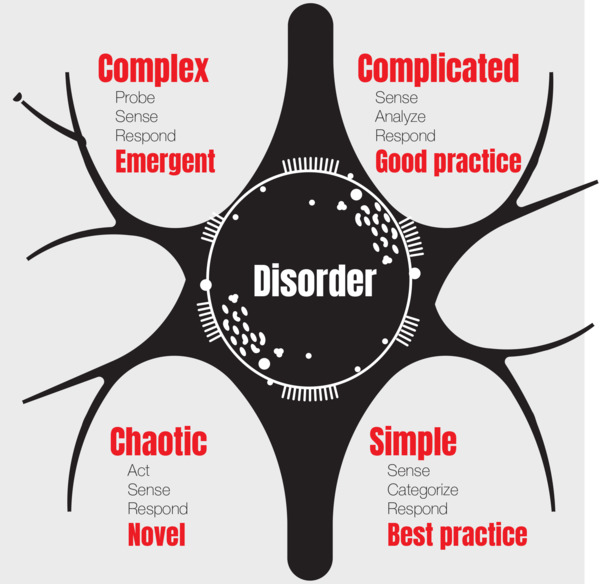

What if all the stakeholders rethought the way they work together instead of planning two years ahead? The Cynefin framework, created by Dave Snowden, could help us reformulate the thinking process. This conceptual model proposes a different approach to aid decision-making and solve different kinds of problems. The idea of the Cynefin framework is that it offers decision-makers a “sense of place” from which to view their perceptions.

The Cynefin framework introduces 5 domains: simple, complicated, complex, chaotic, and a centre of disorder. The different domains help us recognise the situation where we are in and select the most suitable decision-making and management style for this context. The simple domain represents the "known knowns". This means that there are rules in place and the relationship between cause and effect is clear. The complicated domain consists of the "known unknowns". There is a relationship between cause and effect, but identifying them requires analysis or expertise. The complex domain represents the "unknown unknowns". Cause and effect can only be deduced in retrospect, and there are no right answers. In the chaotic domain, there is no relationship between cause and effect, so your primary goal is to establish order and stability. The disorder domain: If you don’t know where you are, you’re in “Disorder.” The primary goal is to move you to a known domain by gathering information.

When conducting a project similar to what we have done several times before (e.g., delivery of manual container handling equipment), the context according to the Cynefin framework is the “Complicated domain”. There are several variables in the process, but the experienced product and project personnel are able to analyse and handle the issues. However, when we are creating a novel solution (e.g. a modern terminal with brand new automation systems and digital services), we are actually working in a “Complex domain”. In this situation, cause and effect can only be deduced in retrospect, and there are no right or wrong answers; thus, we need to rely on emergent solutions and experimentation. Cynefin calls this process "probe–sense–respond".

Successful execution requires the partners to focus on agreeing on a final goal where the ultimate solutions will be defined and implemented jointly during the project.

Collaboration at the next level

Let’s take an example. Ambitious investors decide to build an advanced Greenfield container terminal that attracts inland and maritime customers by bringing them high predictability and fully transparent information flow from inland logistics through the container terminal to shipping lines. They decide to start operations with a proven automated container handling system and extend the operation in the second phase by spearheading the latest and unproven industry 4.0 technologies in order to achieve full transparency in the container logistics chain. To achieve their goals, they need to collaborate with several partners, including port authority, civil engineering companies, container handling equipment suppliers, ERP and TOS suppliers, and finally IoT and IT companies for creation of a fully transparent solution that does not yet exist in our industry.

In phase one of the project, they decide to choose their suppliers using a traditional tendering process where the goal is fixed. They decide to do it by defining a functional description of the task at hand and leave the details of the technical solution to the suppliers. In this case, the operator is moving in the “simple” domain, where they assume that they know the final goal and trust the supplier’s ability to handle the final details and make delivery.

In phase 2, we are clearly moving to the “complicated” or even “complex” domain where nobody can yet define the exact outcome. To succeed, the operators need to think how to successfully approach a solution that requires a significant amount of expertise and creativity to evaluate possible scenarios where there are no clear answers. Instead of approaching this the traditional way, they choose an approach that has all the stakeholders working together as an alliance that shares the risks and rewards. This requires a new, agile approach for financial and legal contracts, as well as for the execution of the projects. It also enables learning and encourages greater experimentation than the traditional subcontracting model does. Instead of defining the final system, successful execution requires the partners to focus on agreeing on a final goal where the ultimate solutions will be defined and implemented jointly during the project.

An interesting example of this type of joint approach to finding a solution is the construction project for a 2,327 meters long road tunnel in Tampere, Finland. Rather than having all the stakeholders solve their own problems, their approach was to create an alliance for collaboration, as well as for sharing the risks and potential savings. The principles of the alliance were joint decisions, trust, openness, ideation for improvements, sharing risks and savings, joint agreement of the final target cost of the project, setting the revenue for each stakeholder depending on how well the jointly agreed target was achieved. The authors believe that these principles encourage partners to ideate various scenarios together, speak openly about the risks, raise problems that occur as early as possible, and solve unexpected problems together rather than waiting for the other party to solve their problems. Ultimately, they have a common interest to succeed financially by exceeding the goals and avoiding the biggest risks. By the way, the tunnel project was finished ahead of schedule and under the budget.

Are we already mastering our projects in the best way possible or is there room for further improvement? When the world is continuously changing, we should rethink our approach to complex projects for container terminals. After all, one size does not fit all.

Jari Hämäläinen, Kalmar

Eveliina Vuolli, Kalmar

Jari Hämäläinen (Dr. Tech.), Director of Terminal Automation at Kalmar, is passionate about renewal. He is eager to create value with new business models and technologies, find new models to improve ways of working. During his career, Jari has led various projects, big and small.

Eveliina Vuolli, SW Development Process and Quality Champion at Kalmar, wants to challenge the organization and generate new thinking so that we can improve our way of working in the future. Facilitation, agility, leanness and leadership are all topics that pique her interest.